Product Description

Inox stainless steel cartridges from SPECTRUM are the most durable range of cartridges available. 316L stainless steel meshes are resilient in the toughest of fluid environments of high pressure, temperature and aggressive chemicals and when used for solid particle removal, they benefit from being reusable after a cleaning process.

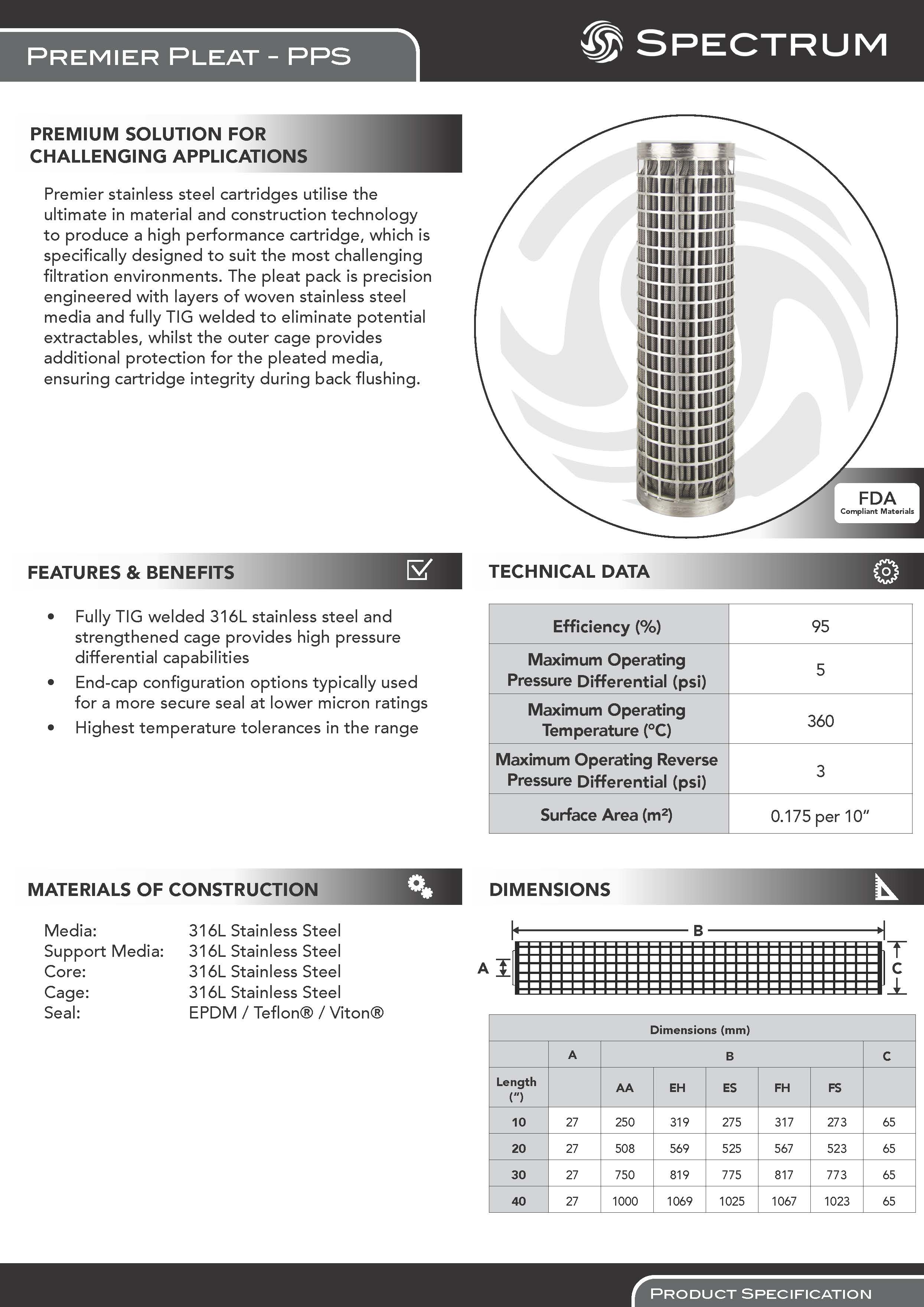

Premier cartridges utilise the ultimate in material and construction technology to create a fully TIG welded cartridge capable of performance in environments where pressure differentials of 5 bar at temperatures up to 360°C exist.

Features & Information

•Constructed from all 316L FDA approved stainless steel, the pleated woven media, support core and fitting are TIG (Tungsten Inert Gas) welded to introduce no other materials

•Higher dirt-holding capacity than the standard pleated range

•The PPS can be cleaned by means of reverse flow, chemical, ultrasonic and high temperature burn-out

•PPS make an economical alternative to conventional polymeric cartridges where environmental issues prevent disposal

•Operating in conditions at up to 300°C and 25 bar differential pressure, these cartridges have the greatest tolerance of the range

•Each cartridge is integrity tested by bubble point in IPA (Isopropyl Alcohol) with data provided at despatch, together with a unique identification number

Applications & Industries

•High viscosity, such as gelatine

•Magnetic coatings

•High temperature specification

•Caustic fluids

•Petrochemicals

•Corrosive liquids and gases

•Chemical solutions

•Straining

Filtration

Filtration  Filter Cartridges

Filter Cartridges  Spectrum

Spectrum  Pleated Filters

Pleated Filters  PPS Inox Premier 316 Stainless Steel

PPS Inox Premier 316 Stainless Steel  PPS-5-10-E : SPECTRUM INOX Stainless Steel Filter 5 Micron 10" EPDM Gaskets

PPS-5-10-E : SPECTRUM INOX Stainless Steel Filter 5 Micron 10" EPDM Gaskets